UGC and workability

The two-fold strategy brings upfront two central ideas to achieve the full potential of UGC in terms of environmental benefits: reduce the clinker content in cement and reduce the binder content in concrete.

Reducing clinker means that the amount of supplementary cementitious materials (SCMs) needs to increase. SCMs have in general higher surface area than cement, and therefore the water demand will likely increase.

Simultaneously, reducing the binder content brings down the volume of paste in concrete, reducing the lubrication between solid particles (aggregates) and reducing flowability.

Workability is then seen as the outstanding challenge to materialize UGC and make compatible the technology with conventional use scenarios of traditional concrete.

Tailor-made chemical admixture formulations to reconciliate UGC and workability

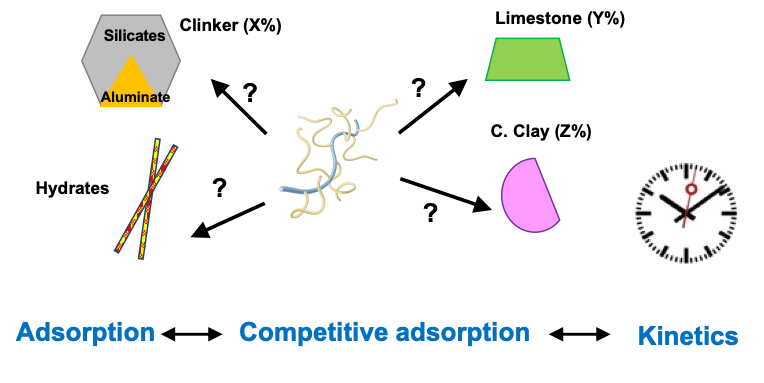

The underlying mechanisms of action of admixtures are complex, involving specific interactions between admixtures and cement as well as among admixtures themselves. In the case of UGC, particularly interesting are the interactions of these molecules with the surface of the SCMs, which will be dominant in the system as the clinker content goes down below 50%.

Many chemical admixtures can delay the cement hydration by modifying the rate of tricalcium silicate (alite) hydration. While this is intended for retarders, it is often undesired for other admixtures as PCEs. PCEs have been shown to hinder the reaction of tricalcium silicate by adsorbing in zones of active dissolution. Managing these effects is scientifically challenging because of the complex interplay of physics and chemistry.

Admixture/surface interactions expected in a multi-component system such as blended cements.

It is imperative to develop new admixtures that enable to overcome these limitations, providing sufficient flowability and flowability retention, without inducing excessive retardation of hydration and consequently, of strength development. Chemical admixtures will be the enablers of the sustainable concrete that this project aims to pioneer.