The UGC technology is founded on its two-fold strategy, which considers:

- Reduce the amount of clinker in cement substantially below 50%, maximizing the use of mineral additions such as calcined clay, limestone and others.

- Reduce the amount of binder (hydrated paste) below 250 kg/m3 per cubic meter of concrete, using state-of-the-art admixture formulations to tackle the workability challenges.

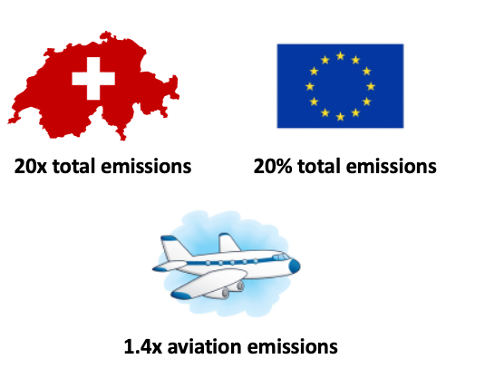

UGC will therefore be the next breakthrough in sustainable technologies for decarbonization of the construction industry, saving at least 800 Mt of CO2 per year, equivalent to 2% of the total anthropogenic carbon emissions or 20 times the total carbon emissions of Switzerland (20% of the EU emissions). This massive reduction of CO2 emissions could also be compared to offsetting about 1.4 times the CO2 associated with the world’s aviation industry in a year, removing 173 million cars from the streets, shutting down 205 coal power plants or installing 172 thousand wind turbines. We would need an entirely new forest of the size of the whole EU to offset the same amount of carbon. Furthermore, the same tools, techniques, workforce and building design approaches currently in use will be applicable.

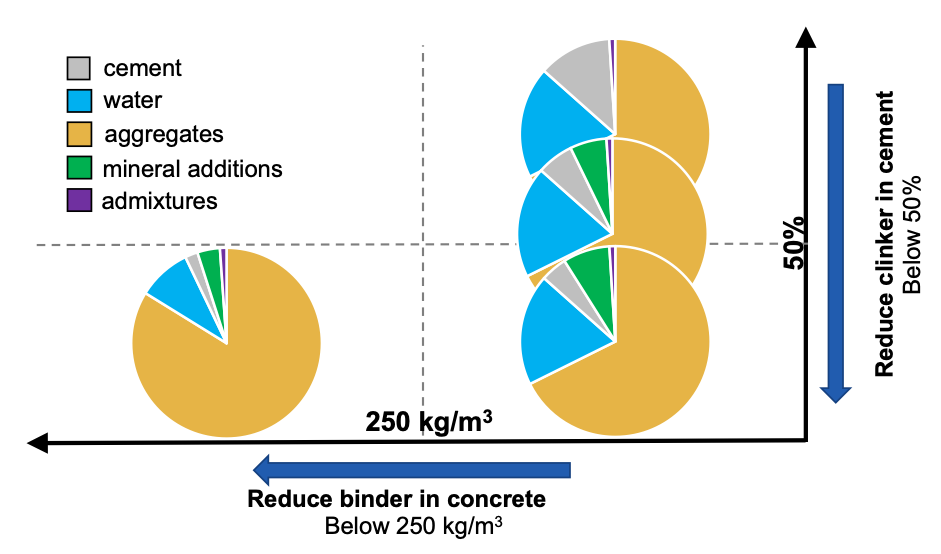

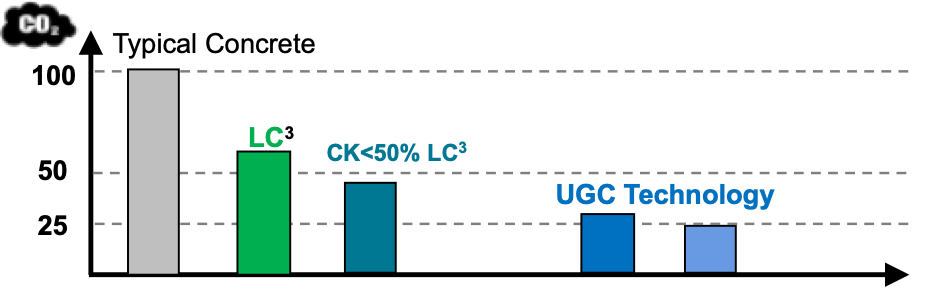

The UGC technological concept can be visualised on the double axis diagram on the right. Starting from a traditional concrete mixture design, clinker can be reduced below 50% if highly reactive mineral additions are used (such as calcined clays). However, cement cannot be completely removed, and there is a lower limit (maximum substitution level) at which basic properties of the material are compromised.

Reducing the binder content in concrete (total amount of cementitious material per cubic meter of concrete) unlocks a second avenue for CO2 savings. It is by taking both components of the two-fold strategy simultaneously that a concrete with about a quarter of the embodied CO2 of the reference can be produced (or about half of a concrete that only incorporates, for example, LC3 cements).

It is widely accepted that modern concrete contains more cement than is actually needed. The reasons behind this are diverse: some national standards prescribe the minimum binder content for different durability exposure classes, they can also be relatively arbitrarily specified on a project basis, importantly also there is often a lack of availability of multigranular aggregates to improve packing and finally there is tradition. As an example, the EN-206 standard for concrete prescribes minimum cement contents between 280-300 kg/m3 for the most common exposure classes. In the US, a minimum binder content is not prescribed by standards but is commonly specified in projects, falsely believing that this will ensure high quality concrete. Such situations are however not static and can evolve substantially as more data becomes available and the pressure for low carbon concrete increases.

Conceptually, the binder volume (cement plus water) should be enough to fill the voids between the aggregates. As previously mentioned, from a geometrical point of view, this leads to values around 200 kg/m3 for well graded (highly packed) aggregate size distributions. The minimum binder contents were originally specified to ensure workability, when modern superplasticizers such as PCEs were not available. However, this technical limitation is not currently justified, and the massification of admixtures enables their use in a cost-effective manner.

In UGC, the volume of aggregates is increase above the traditional 70% to reduce the amount of paste below 30%. This is achieved by optimizing the packing of the aggregate skeleton in combination with modern superplasticizers.