Concrete was, is, and will remain, the choice to build our cities. Consequently, the most effective way to reduce the CO2 footprint linked to this development is to reduce the clinker content in the concrete that will be used. This has oriented the industry towards an increasing adoption of blended cements, that incorporate supplementary cementitious materials (SCMs) replacing part of the clinker with a low carbon substitute.

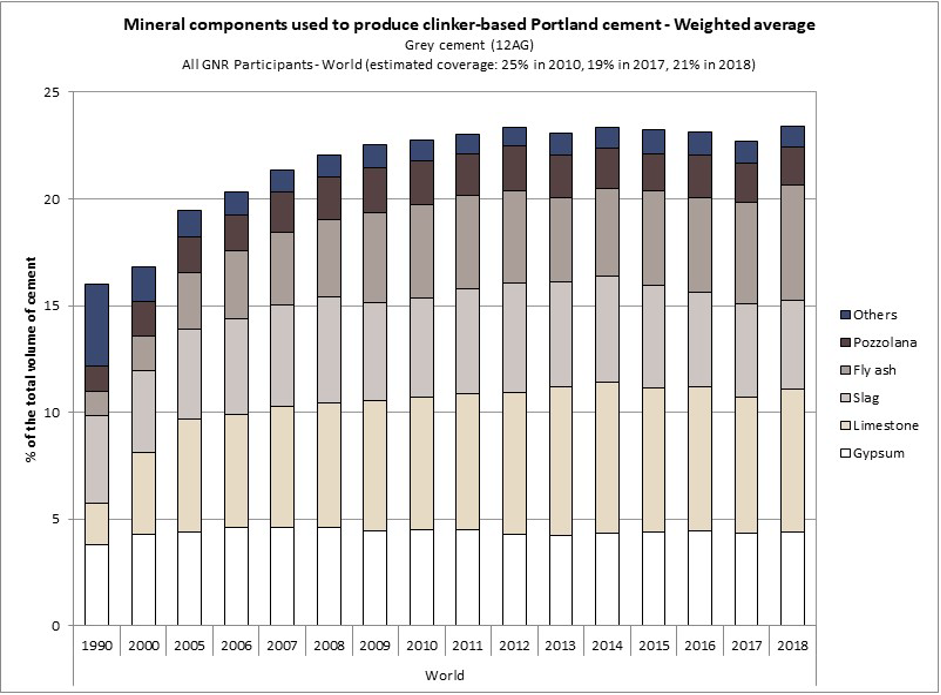

The availability of commonly used SCMs such as fly ash (by-product of burning coal) and slag (by-product of iron production in blast furnaces) is limited (about 10-15% of the total PC production) and, especially in the case of fly ash, expected to decrease in the forthcoming decades. In the case of limestone and natural pozzolans, the substitution level is in general limited by the lower reactivity of these materials in cementitious systems. This has limited the world substitution level of clinker by SCMs to about 20-25%, without major improvements in the last 10 years.

Mineral components used to produce clinker-based Portland cement (by wt. %). Based on the GNR database.

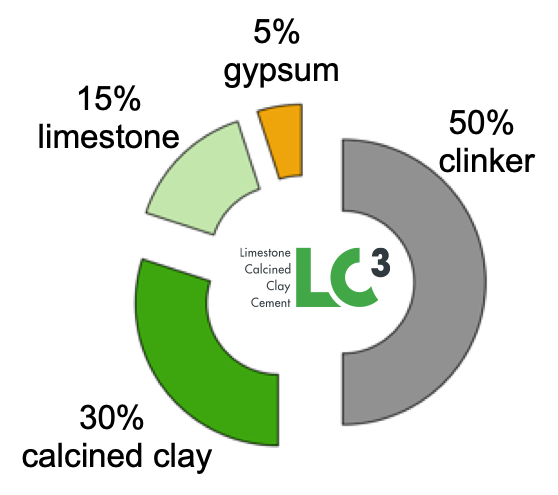

On the contrary, kaolinitic clays and limestone are available in virtually unlimited quantities, and can enable a significant worldwide reduction in PC content. Limestone calcined clay cements (LC3), a project originated and developed mainly at EPFL in Switzerland, are a family of multi-component cements that incorporate limestone and calcined kaolinitic clays replacing up to 50% of clinker. They achieve similar strength to conventional PC from 7 days onwards. Overall, LC3 cements can save between 30 to 40% of the CO2 emissions per ton of cement produced compared to PC.